You are reading the older HTML site

Positive Feedback

ISSUE

29

halcyonics

Micro 40 Isolation unit

as reviewed by Will Wright

|

WILL WRIGHT'S SYSTEM

LOUDSPEAKERS

ELECTRONICS

SOURCES

CABLES

ACCESSORIES

|

Looking back at High End Audio trends over the years, I find the inventiveness and creativity of the industry fascinating. The evolution of the cable industry comes immediately to mind, as do those curious acoustic tweaks such as little stands or columns. Then there are the wooden pucks on top of speakers and components, oriented just so, dots attached to walls and windows or inside components, sprays and CD treatments. Everyone has favorites, I suppose.

A burgeoning trade has now developed in isolation devices, those items that, in theory, help isolate your components from air borne and structure borne vibration. Just how important are these devices, really? Some have argued that if a component such as a CD player is correctly constructed with an eye to structural rigidity, then it shouldn't need any additional help, especially if it is a high dollar, High-End item. Shouldn't we expect that manufacturers who spend considerable time "voicing" their work would take isolation into consideration? And, if they do (and some definitely do), what additional effort should be needed?

Others may argue that, aside from a turntable, which is known to need isolation, and tube equipment, known to be sensitive to microphonic effects, the level of a component's exposure to vibration is low enough to be ignored. Clearly not everyone agrees with this philosophy. Since supply and demand strongly dictate what gets marketed, the sheer number and variety of isolation devices would indicate that a significant number of audiophiles consider them important, even necessary. How did this get started?

TipToes

Remember these, circa 1984? Of all related devices, variations on the lowly Mod Squad TipToes have been the most ubiquitous. Tall and short, fat and thin, brass, aluminum, titanium and so on, this is arguably the device that started the "isolation" craze. The dominant effect here is more one of coupling a piece of equipment to its support rather than actually isolating it. Essentially, this coupling changes the effective mass of the equipment, thus changing the natural resonant frequency. Depending upon the circumstances, the shift in resonant frequency could put it in a range that no longer encourages deleterious vibration effects in equipment. It works very well on some things, not so well on others. Understanding this principle, however, does allow for some experimentation. If your speakers are on spikes (or even if they are not) try putting a couple of barbell weights, or other heavy object, on top. The added mass usually tightens the bass a bit. This works on electronics as well.

The only actual isolating effect in play with TipToes comes from their cone shape. Point down, unless the path of vibration is totally vertical, a portion of the vibration energy will be dissipated in displacement of the supporting shelf, rather than be transferred to the equipment. It's a very minor effect and due more to the compliant nature of the shelf. On the other hand, assuming good coupling of the cone surface and the component chassis, energy originating inside the component is forced by the cone shape to be almost completely vertical, thus maximizing drainage of internal vibration to the supporting structure.

This rudimentary concept is taken even further by the recent rash of devices that can basically be described as a ball bearing in a cup, such as Aurios and Rollerblocks, for example, which attempt to account for positional displacement (vibration) by rolling. However, rolling itself creates noise. In addition, the size, mass and sphericity of the ball and cup have associated resonances, which will limit maximum effectiveness to a specific frequency range, also influenced by equipment weight and chassis compliance.

Sorbothane

This urethane derivative is described as a visco-elastic polymer combining isolation and damping characteristics. The desired effect is to translate vibration in the component to low grade heat dissipated by the Sorbothane. Some people really love this stuff and I admit I tried it throughout my system many years ago. ("Tuning" a system is a process of discovery.) Though conceptually I could see the potentially beneficial characteristics of Sorbothane, I was never able to apply it satisfactorily in my own system.

Carbon Fiber

Lighter than aluminum and stronger than steel, so they say, carbon fiber has found its way into everything from airplane composites, boats, cars and bicycle frames, among other uses. The best known audio application of carbon fiber is Black Diamond Racing's line of shelves, cones and various pucks, but carbon fiber has also been used extensively in turntable/tonearm applications and is prized for its rigidity, light weight and high damping rate characteristics.

This is a product that I have put to considerable use in my own system. Up until very recently, all my equipment including my speakers sat on carbon fiber. For example, the two Krell power amps each sit on a combination of cones and pucks under a Black Diamond Shelf, with additional cones and pucks on top of the shelf. On top of each amp is another set of cones and pucks and on top of that, the whole shebang is mass loaded with a three-inch thick granite machinists plate.

Isolation Platforms

Once the isolation craze really started to take off, isolation platforms evolved as a product category. One of the first to gain the attention of audiophiles was the Vibraplane, an industrial isolation platform conceived for use under such exotic items as electron microscopes, and adapted for use under turntables. The functionally related High End Audio oriented Townsend Seismic Sink also made its appearance. Both devices use an airbladder to float the component on an "air spring."

Since that time, many products have come to market employing their own unique take on the isolation platform, including the use of magnets to float the equipment. Another interesting approach is the use of constrained-layer damping, wherein a visco-elastic material is sandwiched between two rigid plates, forcing any vibration induced bending of the plates to transfer shearing forces to the visco-elastic material, to be dissipated as heat. Many of the currently available products use some combination of the techniques discussed here plus other patented techniques. I apologize if anyone's favorite has been left out. Before moving on, I'd like to point readers to two other interesting products.

The Minus K isolation platform is said to provide vertical-motion isolation via a stiff spring that supports a weight load, combined with a negative-stiffness mechanism (NSM). The net vertical stiffness is made very low without affecting the static load-supporting capability of the spring. Beam-columns connected in series with the vertical-motion isolator provide horizontal-motion isolation.

The Critical Mass Systems isolation platforms are said to employ a mapped sequence of narrow, intermediate and wide frequency band filters that convert mechanical energy to low grade heat at a highly accelerated rate. The result is overlapping energy conversion networks that work in harmony to reduce distortion.

Here's the thing

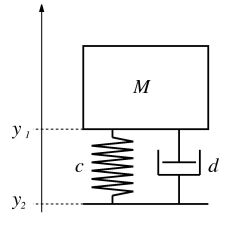

All of the techniques and products discussed so far fall into the category of passive isolation. (Now, before writing in to explain that the Vibraplane employs an active system, please note that it is only active in the sense that it monitors and maintains the correct air pressure. The isolating mechanism itself is still passive.) The mechanics behind passive isolation, in its simplest form, will look something like the configuration shown in the following diagram, utilizing some combination of mass (the component), spring and damping, and comprises a mechanical low pass filter.

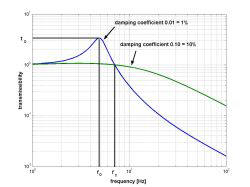

Unfortunately, all passive systems of this type have an associated resonance frequency, in which incoming vibration is amplified within the resonance zone. These are tuned systems. Increasing the damping will reduce resonance amplification, but will also reduce isolation at frequencies above the resonance zone. Clearly, this limits the amount of damping that can be applied if good isolation is to be achieved. Most passive systems are tuned to provide isolation above about 5 Hz, and do not provide isolation below this tuning frequency. The effects of these resonance zones can be, and frequently are, audible.

So, if vibration energy impinging upon the isolation device falls within the device's resonance zone, this energy will not only pass through to the component, it will be amplified in the process. A graphic example of this can be seen with turntable suspension. If the frequency of record wow and warp overlaps with the turntable/tonearm suspension tuning, very significant woofer pumping may be seen, which in turn can cause power supply modulation in the amp. Mistracking may also occur.

Halcyonics

From the look of their website to the straightforward professional manner presented in the user's manual, referred to by Halcyonics as Operating Instructions, and right down to the laboratory chic of the Micro 40's industrial look, everything here is about engineering. Like the Vibraplane, Halcyonics products were conceived, designed and built for industrial applications. When initially approached by Sam Laufer, now the U.S. distributor, regarding the use of Halcyonics isolation platforms for audiophile applications, company reps admitted that this had never before occurred to them.

Originally founded in 1996, Halcyonics systems are used in many fields of advanced micro- and nanotechnology including biotechnology, material sciences, semiconductors and LCD manufacture, and offer the experience and support power of a manufacturing company with everything under the same roof. But, unlike the other approaches discussed earlier, Halcyonics products use active isolation. This is accomplished by using a vibration sensor, e.g. an accelerometer, a signal amplifier and a Fast-Fourier-Transformation (FFT) analyzer, thus providing what is referred to as direct velocity feedback. An actuator is driven by a signal proportional to the absolute velocity of the mass: the component once again. This causes different transmissibility behavior than with passive isolators, avoiding the amplified resonance zone.

Where to start?

The first place I decided to try the Halcyonics Micro 40 was under my Esoteric universal disc player. This decision was based on convenience and the assumption that I could best capitalize on the benefits of isolation by using the platform under a source component. I was reluctant to disturb my turntable, fearing that I would need to go through the entire setup ritual to ensure that it was performing at its best after being disturbed.

Unlike the unit pictured on the Halcyonics website, which shows the front control section on the longest face of a rectangle, the review sample had its control section on the narrower face of the unit. To best accommodate the dimensions of my player, the Micro 40 was placed sideways on the equipment stand, as seen in the photo. A master power switch on the back of the Micro 40 controls main power. Once powered up, all control is via the menu driven display. A series of options, which include weight adjustment on/off/locked, isolation on/off and sensitivity on/off/locked, is straightforward. Upon exiting the menu, the platform begins its adjustments. There are eight servos (4 for vertical and 4 for horizontal) and these can be heard as they prepare to isolate the component. Once the servos complete their activity the unit automatically switches isolation on and adjustment off. You are now ready to listen.

Over the years of surfing the net and lurking in several audio forums, I have heard many technically educated folks contend that, under normal domestic circumstances, a digital based optical disc player will sound the same regardless of various tweaks applied, including disc treatments and isolation footers. In this view, because the data is stored digitally, if the player can read the disc, the job is done. I remember wishing that some of those people were in the room when I played the first disc with the Micro 40 under my universal player. The most obvious change was the removal of an underlying resonance. This is an effect hard to describe but easily heard. An inherent part of the sound of my system had changed. I had always attributed this resonance to the speaker system, but here was proof that some other mechanism was at work. It was revelatory. In fact, in every application I tried with the Micro 40 it consistently improved sound quality while adding nothing of its own.

Overall articulation was extraordinary, particularly in the bass. Soundstage, transparency, detail, all were enhanced. Man, I was flying! A marathon listening session ensued. I played CDs, SACDs and DVD-As on into the night. I was pulling detail out of what I had thought of as murky sounding CDs. Previously unintelligible lyrics separated themselves from the mix. My prior experience with High Resolution formats had been a mixed bag. Sometimes the difference between Hi Res and regular Redbook CDs was subtle. But with the Halcyonics isolation at work, Hi Res discs stepped further ahead, as if better use was being made of the resolution on tap. I placed a small nine-inch by eight-inch Black Diamond Racing shelf on top of the universal player to see if the additional mass or damping had an effect. I immediately removed it. That beautiful bass performance had been deadened.

Shades of RoboCop! When I opened or closed the disc drawer in the process of changing musical selections, the Micro 40's servos would growl and whir. The effect could be a little startling. Whoa now, easy big fella! The problem was solved whenI discovered that the active weight adjustment sensitivity could be turned off after initial setup. My listening room is in the basement of my house and is about half underground with a tile over concrete slab floor. Even so, the Micro 40's basic display showed that its sensors detected anyone walking in the room. Impressive.

Coincidentally, just prior to arranging to review the Halcyonics Micro 40, I had ordered two Critical Mass Systems Grand Master isolation platforms (see Brutus Awards in Issue 28). It was at about this time that they arrived. These platforms had been ordered specifically sized and configured for use under my two main source components, consisting of a Turntable and a Universal player. This seemed to be a good time to move the Halcyonics Micro 40 to turntable duties. I placed the Critical Mass Grand Master under my universal player and moved the Micro 40 under my turntable. This left me with an extra Grand Master, so I placed that under my preamp.

If anything, results using the Micro 40 under my turntable were consistent with my expectations, yet slightly more subtle than those under the universal player. Though at first this surprised me, I attributed it to the fact that the turntable has its own suspension. Still, all the positive comments above apply here as well. Marathon record listening ensued.

After such great success with the Halcyonics Micro 40, I decided to look for other applications to gain additional perspective. I contacted Mike Lavigne, also a PFO reviewer, to see if he would be interested in a test drive. (See Mike's recent reviews or surf the "Meet the Writers" section on line to get the rundown on his latest system.) Mike was very interested in a demo and a meeting was quickly arranged. Based on the good results under my universal player, we decided that an excellent place to test the Micro 40 in his system would be under his EMM Labs digital transport. We spent some time listening to his stock setup to get our ears adjusted, and then slipped the Micro 40 under his transport, which already sits on a Grand Prix Monaco equipment stand with Formula Shelves, and includes Apex footers and SE frame. We played one of the previous selections for comparison. Mike's comment: "I'm gonna need at least three of these!"

Back at home, after spending quite some time in the latest configuration with the Micro 40 under my turntable and the Critical Mass Systems Grand Master platforms under the universal player and preamp, I decided it was time to try out the Grand Master I had purchased to go under my turntable in its intended application. At first I had planned to move the Micro 40 back under my universal player, but after pulling it out from under the turntable to install the Grand Master I got lazy and decided "what the heck, I'll put it under my preamp instead," just temporarily.

Much to my surprise, I ended up preferring this configuration. Although this is most probably not where I would have ended up without the Grand Master platforms to go under my source components, this configuration provided the best overall performance for the whole system. Whether spinning records or optical discs, the results were sublime. My preamp absolutely loved the Micro 40 and as a result, so did I. This was unexpected. In fact, I would have expected my previous configuration of Micro 40 under turntable and Grand Master under preamp to be superior.

After living with this configuration for a while, I had an epiphany. The specs for the Micro 40 list its load capacity as 100 Kg (220 lbs) and I was nowhere near that. So I placed my Sutherland PhD phono stage on the Micro 40 and the preamp on top of the phono stage. Once the Micro 40 was readjusted to the new load, it appeared unfazed by the change. This setup was fabulous and addictive. If I tried to play music while I went in the other room to work on the computer, I would inevitably be drawn back to the listening seat.

One thing I had planned to do in the context of this review was to try the Micro 40 under tube based equipment. Since my current system is all solid state, this would have meant involving another audiophile friend in the experiment. I may yet get the chance, but as of this writing, I haven't done so. I mention it here because, due to the sensitivity of tubes to microphonics, I believe this application could provide significant results for fans of this technology. If any of our readers get the opportunity to try this, I'd welcome an email detailing your experiences.

Are we there yet?

At this point, I tried experimenting with the shelf material under the Micro 40. The original support for the preamp had been a three-inch thick granite machinist plate sitting on top of an equipment stand. The sound, though excellent, was a little more forward than I'm used to. I thought the granite was storing energy, so I replaced it with a one-inch thick plywood shelf and this improved the balance somewhat. It is interesting to note that I didn't have this issue when using the Micro 40 under source components. Although I like the clarity and overall system performance provided when using the Micro 40 under the preamp, I am not completely satisfied that the optimal system balance has yet been achieved. My experiments continue.

The Software

The rear panel of the Micro 40 is equipped with a USB port for connection to a computer. The included software is Windows PC based and is intended to assist the user in finding the best location for the platform and for running a technical test of the entire system. Front panel functions can also be controlled from this interface. The four available subroutines are Diagnostic, Monitor, Spectrum and Location. These subroutines and their associated display screens give a much clearer view of the vibration effects and the isolation provided by the Micro 40, providing information about the spectrum and frequency of the vibration energy in which components are submerged.

The intended application of the Location subroutine is to allow the recording and storing of vibration information in order to guide the user to optimal placement. It occurred to me that it could also be used to determine the effectiveness of different support materials upon which the Micro 40 was placed in a single location; for instance, the difference between the isolating properties of a three-inch thick granite machinist plate and a one-inch thick plywood shelf, or to determine the effectiveness of other isolating devices or isolation platforms by graphically displaying the spectrum and frequency of vibration energy. During experimentation it was noted that this was best achieved with the Micro 40 loaded with a component as opposed to just free standing.

Conclusions

The ambient noise level, i.e. vibration, in typical domestic environments is commonly 35 to 40dB. Among the sources of this air and structural borne vibration energy are HVAC systems and appliances such as washer/dryers, refrigerators and dishwashers. We are literally bathed in noise and vibration. Our ear/brain mechanism allows us to tune out much of the ambient noise so that we become unaware of it. Other sources of noise include traffic, heavy machinery and wind, all of which propagate through structures as traveling waves. In urban areas there is actually much more of this type of low frequency structural borne energy around us than one would expect.

The most obvious source of vibration is that coming from the speakers and then fed back through the audio equipment. I admit I was surprised by how much these combined mechanisms contributed to distortion in my system. Though we may be conditioned to the ambient noise levels, our equipment is not. If a system is voiced for a balanced sound with this distortion mechanism present, adding the Micro 40 may lean out the sound enough to require some adjustments elsewhere. I can't fault it for that.

The Halcyonics Micro 40 has made a believer out of me. In every application I tried, the Micro 40 reduced distortion and improved musical detail retrieval and articulation. I could find no circumstance in which I could attribute negative results to this technology. Some audiophiles will be deterred by the somewhat industrial looks, and others by the price. Passive isolation platforms may get you 90 percent of the way there at a quarter the price, but if you want the full enchilada you'll just have to pony up. Unlike most passive isolation technologies tuned to provide isolation starting at about 5Hz and up, the Micro 40 begins isolation at 0.6Hz. and is already providing 25dB of isolation by 5Hz. I suspect that anyone able to try a Halcyonics product will be as surprised, and as pleased, as I was at the results. Highly recommended. Will Wright

Micro 40

Retail USD: $7500

Halcyonics GmbH

Tuchmacherweg 12

D-37079 Goettingen - Germany

TEL: 551-99 90 62-0

web address:

http://www.halcyonics.com

In the USA

Halcyonics, Inc.

935 Hamilton Avenue

Menlo Park, CA 94025

TEL: (650) 322-6600

The US Distributor

Sam Laufer

[email protected]